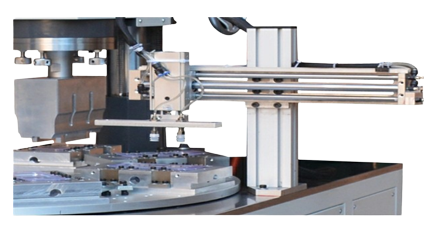

Ultrasonic Rotary Table Welding Machine

This Machine is specially developed by Avni Industries for Whom their production rate is very high but they wants to save labor and time.

This Machine’s rotary system is very robust combination of Mechanical Index System , Motor and Reducing gear Box.

Machine can be designed with desired station and desired wattage Ultrasonic system as per customer Requirement.

Key Features :-

Variable speed, * Auto ejection ,* Choice of Station4, 8 or 16 Stroke length 75mm or can be customize (25mm~100mm) Ultrasonic system as per requirement.

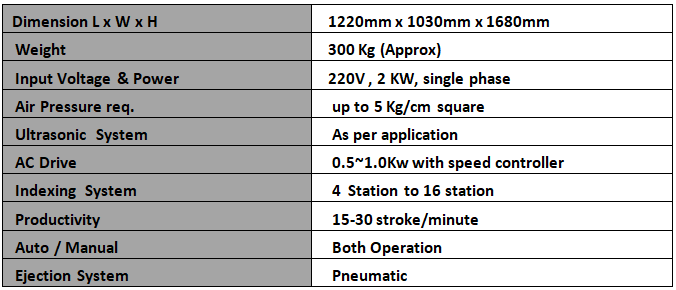

Technical Specificaton of Ultrasonic Rotary Table Welding Machine:-

Frequently Asked Questions (FAQs)

An Ultrasonic Rotary Table Welding Machine is a specialized piece of equipment used for joining thermoplastic components using high-frequency ultrasonic vibrations. It features a rotary table that indexes parts to be welded, making it suitable for high-production applications.

The machine employs ultrasonic technology to create a strong bond between thermoplastic parts. It typically consists of a rotary table that moves parts into the welding station, where ultrasonic vibrations are applied to create the weld. The rotary table indexes parts, allowing for continuous and efficient production.

Ultrasonic Rotary Table Welding Machines are versatile and can be used to join various thermoplastic materials, including but not limited to ABS, PP, PC, PVC, and PET, depending on the machine’s specifications.

- High production efficiency and speed

- Consistent and high-quality welds

- Suitable for mass production

- Minimal waste and environmental impact

- No need for additional adhesives or fasteners

- High production efficiency and speed

- Consistent and high-quality welds

- Suitable for mass production

- Minimal waste and environmental impact

- No need for additional adhesives or fasteners